We are working to develop a world with “smart” bearings

Engineering

With the dawn of the electric vehicle and the emergence of new ways of driving, companies ties to the automotive sector are facing new challenges that test their ability to adapt.

Technology, alongside teamwork with other innovative players, is a strong impetus for companies that, like us, want to move towards a new way of understanding the automotive component industry. This is the reason why our engineering centers lead the Network for Bearing Excellence (NBE).

The NBE is comprised of a network of professionals and technology and test centers in constant search for excellence in bearing solutions. The following agents are part of our network of collaborating centers:

Being at the forefront allows us to look ahead. That is why at Fersa, we have proposed four new ways of developing the bearing of the future to face the big challenges of today's world:

- Integration and new functionalities.

- Environmental care and the pursuit of efficiency.

- Digitization and the promotion of smart and connected technologies.

- The era of electric and hybrid mobility

Integration and new functionalities.

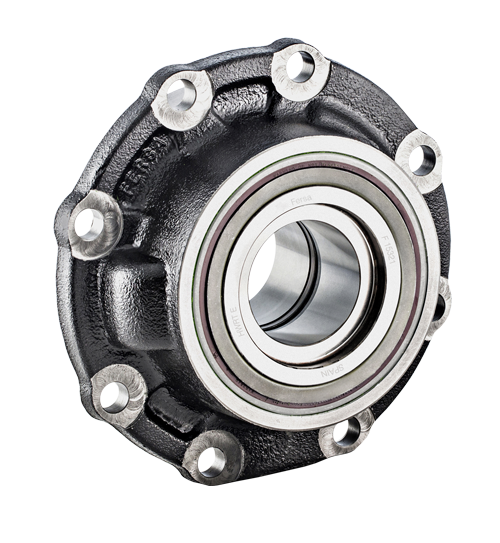

At Fersa we have developed complete solutions that do not require maintenance, simplify assembly, and guarantee sealing and precision. We thus guarantee that the workshop assembles a suitable bearing that is calibrated and pre-adjusted at the factory, with all components correctly assembled. Examples of this are our preset bearings and pinion modules. In addition, our bearings can create solutions to the specific problems of the environment in which they will operate, presenting a new variety of features unrelated to those of the component.

Environmental care and the pursuit of efficiency.

Energy efficiency and vehicle consumption reduction are increasingly being demanded by users and manufacturers. That is why we have developed a wide variety of bearings focused on improving efficiency:

- Hi Pro: bearings with high durability and good energy efficiency.

- Hi Pro FE: high durability bearings, which reduce friction by 10% and have high levels of efficiency.

- Hi Pro PD: specially designed to reduce size (they weigh 10% less than a standard bearing) while maintaining its durability and decreasing friction by more than 15%.

- Ultra Pro: our latest development that can triple the life expectancy of a standard bearing.

- G Pro: bearings with engineering coatings to reduce wear and friction by up to 40%.

Digitization and the promotion of smart and connected technologies.

In this area, Fersa has developed the MOSS Bearing range, with bearings that incorporate sensors to measure variables such as temperatures, vibration, humidity, loads or speed, among others. It is a wireless system incorporated into the bearing, which is self-powered with the normal component workings and which facilitates and speeds up the vehicle's maintenance in real time, without the need for dismantling.

The era of electric and hybrid mobility

At Fersa, we offer a Hybrid Bearing range with bearings that incorporate ceramic components that adapt to these particular needs, such as electrical insulation, turning at higher speeds and reducing vibrations.